Tackling Tricky Car Chores: China’s Revolutionary Robot Assistants

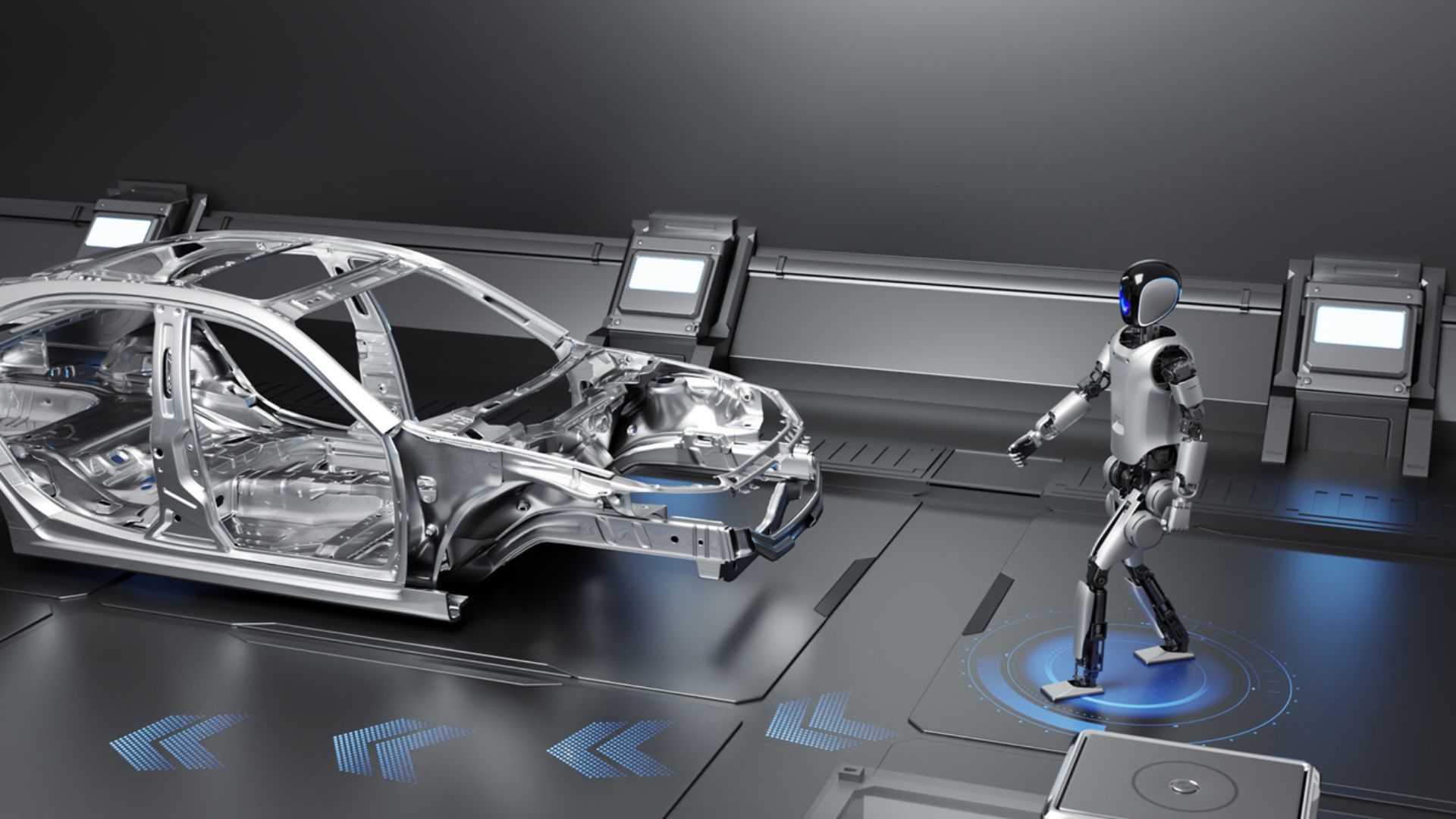

Imagine a future where robots are an integral part of our daily lives, assisting us with tasks that were once considered impossible for machines to accomplish. Dongfeng Motor, a leading automotive manufacturer in China, is pioneering this future with their groundbreaking humanoid robots. These highly advanced and versatile machines are developed to tackle tricky car chores, revolutionizing the automotive industry. In this article, we will delve into the world of Dongfeng Motor’s humanoid robots and explore their potential impact on the car industry.

Mastering Car Chores with Cutting-edge Technology

Dongfeng Motor has recognized the need for smart solutions to streamline car production processes. The introduction of their humanoid robots marks a significant step towards achieving this goal. Equipped with cutting-edge technology, these robots are designed to assist automotive workers in a wide range of tasks, making the overall production process more efficient and precise.

From welding car parts and assembling components to painting and quality control, these robots excel in performing tedious and challenging tasks. They are built with advanced sensors and AI algorithms, enabling them to adapt to dynamic environments and collaborate seamlessly with human workers.

Unmatched Precision and Efficiency

One of the striking features of Dongfeng Motor’s humanoid robots is their unmatched precision and efficiency in carrying out complex mechanical tasks. These robots are meticulously programmed to perform repetitive tasks with utmost accuracy, reducing the margin of error significantly. With their exceptional skills in welding and assembling, they surpass traditional robots and human workers in terms of both time and quality.

Unlike human workers who may experience fatigue or distractions, these robots can tirelessly work on tasks that demand high levels of concentration, ensuring consistent excellence in their performance. By leveraging their computational power and sophisticated algorithms, Dongfeng Motor’s humanoid robots streamline production lines, maximizing efficiency and minimizing delays.

Enhancing Safety and Ergonomics in the Workplace

Another key advantage offered by the integration of humanoid robots is the improvement in safety and ergonomics within the workplace. Car manufacturing involves tasks that may pose risks to human workers, such as heavy lifting or exposure to hazardous chemicals. By delegating these tasks to the humanoid robots, Dongfeng Motor prioritizes worker safety, ensuring a healthier work environment.

Furthermore, these robots are designed with ergonomics in mind, allowing them to perform tasks effortlessly without straining their mechanical systems. This breed of robots minimizes the chances of repetitive strain injuries or accidents, safeguarding both the humans working alongside them and the products they create.

Impacting the Future of Automotive Industry

The introduction of Dongfeng Motor’s humanoid robots has far-reaching implications for the future of the automotive industry. With these robotic assistants, car manufacturers can optimize their production processes and achieve higher output without compromising on quality. Their unrivaled precision and efficiency ensure that each vehicle manufactured meets the stringent standards set by the industry.

This innovation not only promises increased productivity but also cost savings. By automating repetitive and labor-intensive tasks, companies can allocate their human workforce to higher-value activities, amplifying their productivity and driving overall growth. It empowers workers to focus on tasks that require critical thinking, creativity, and problem-solving skills, thereby utilizing their expertise to its fullest potential.

Frequently Asked Questions

Key Takeaways:

Conclusion

The emergence of Dongfeng Motor’s humanoid robots marks a significant advancement in the field of robotics and automation. These groundbreaking machines are revolutionizing the automotive industry by streamlining production processes, enhancing efficiency, and ensuring top-notch quality. With their precision, adaptability, and collaboration capabilities, these robots are set to shape the future of car manufacturing, benefitting both manufacturers and workers alike. As we embrace this robotics revolution, it is crucial to strike a balance between automation and human creativity, as together they hold the potential to drive innovation like never before.

Source: insidertechno.com