Key Takeaways:

Revolutionizing the World of Tribology with Game-Changing Artificial Neural Networks

Are you ready to be amazed? Prepare to witness a monumental breakthrough in the field of Tribology. In this article, we will explore how Artificial Neural Networks (ANNs) are revolutionizing Tribology, unlocking new possibilities and transforming industry practices. Leave aside your preconceived notions and let’s dive into the world of intelligent machines and their applications in tribological phenomena.

The Rise of Artificial Neural Networks

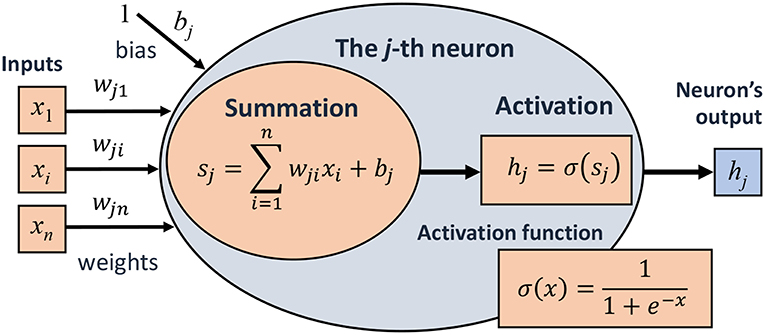

In recent years, Artificial Neural Networks have drawn significant attention and are now widely utilized in various fields. These networks mimic the structure and functioning of the human brain, enabling machines to process and analyze complex data sets efficiently. Leveraging this revolutionary technology, scientists and engineers are now exploring its applications in Tribology, the study of friction, wear, and lubrication.

Unveiling the Potential: Predicting and Optimizing Friction and Wear

The sheer complexity of Tribology demands continuous exploration to improve efficiency and performance. Traditional approaches have been unable to capture the intricate nature of friction and wear phenomena effectively. This is where Artificial Neural Networks step in as game-changers.

With their ability to learn from extensive datasets and recognize intricate patterns, ANNs offer unparalleled predictive capabilities. Through careful training, they can analyze a multitude of variables and deduce frictional behavior accurately. Engineers can now model and predict the tribological responses of various systems, ranging from simple mechanical devices to sophisticated industrial machinery.

By analyzing data points such as material properties, lubricant conditions, and environmental factors, ANNs can predict wear rates, identifying critical components that require attention and maintenance. This helps industries optimize maintenance schedules, reduce downtime, and ensure maximum productivity.

Lubrication Optimization: Redefining Efficiency

Efficient lubrication plays a pivotal role in minimizing friction, wear, and energy consumption. Conventionally, lubrication plans were based on generalized guidelines, resulting in over-lubrication or under-lubrication scenarios. The meticulous analysis of ANNs offers a groundbreaking alternative.

By analyzing factors such as temperature, load, speed, viscosity, and surface roughness, ANNs help engineers refine lubrication processes. With an accurate assessment of these variables, tribological systems can be optimized to achieve the perfect balance between performance and energy consumption. The integration of ANNs with online monitoring systems further enhances this optimization process, resulting in real-time adjustments and improvements.

Industry Applications: Unlocking New Horizons

The applications of Artificial Neural Networks in Tribology are boundless, transcending industries and driving innovation in multiple sectors. Let’s explore some areas where this revolutionary technology is making its mark:

Automotive Industry:

ANNs are transforming the design and manufacturing of vehicles. By accurately predicting friction and wear patterns, engineers can optimize engine performance, reduce emissions, and extend component lifespan.

Manufacturing Industry:

ANNs assist manufacturers in optimizing machining, minimizing tool wear, and enhancing overall operational efficiency. With real-time analysis, they can adjust process conditions to achieve maximum output while reducing energy consumption.

Energy Industry:

In energy production, ANNs optimize tribological interactions in turbines, reducing energy loss, and increasing the overall efficiency of the power generation process. From wind turbines to thermal power plants, Tribology powered by ANNs paves the way for a greener and more sustainable future.

Why Embrace This Revolutionary Chang?

The integration of Artificial Neural Networks in Tribology heralds a new era of efficiency, predictive maintenance, and improved performance. Embracing this paradigm shift offers numerous benefits:

- Enhanced system reliability: Increased accuracy in predicting wear and friction behavior reduces unexpected failures, improving overall reliability.

- Optimized lubrication processes: Tailoring lubrication plans based on precise variables ensures efficient performance while reducing energy consumption.

- Predictive maintenance: Identifying critical components through wear rate predictions enables proactive maintenance planning, reducing downtime and increasing productivity.

- Cost savings: With ANNs optimizing friction and wear behavior, industries can reduce operating costs associated with maintenance, repairs, and component replacement.

Frequently Asked Questions

Conclusion

Artificial Neural Networks are revolutionizing the world of Tribology. Their predictive capabilities provide accurate insights into friction, wear, and lubrication. By implementing ANNs, industries can optimize operations, minimize maintenance costs, and achieve higher efficiency and productivity. As this game-changing technology advances, new possibilities continue to emerge, transforming industry practices and shaping a more informed and interconnected future.

Source: insidertechno.com